Condenser fans are crucial components of air conditioning and refrigeration systems, responsible for dissipating heat from the condenser coils by moving air over them. This process helps convert the high-pressure, high-temperature refrigerant gas from the compressor into a high-pressure liquid, which can then continue its cycle through the system. Here’s an in-depth look at condenser fans, including their types, features, applications, and maintenance:

Overview of Condenser Fans

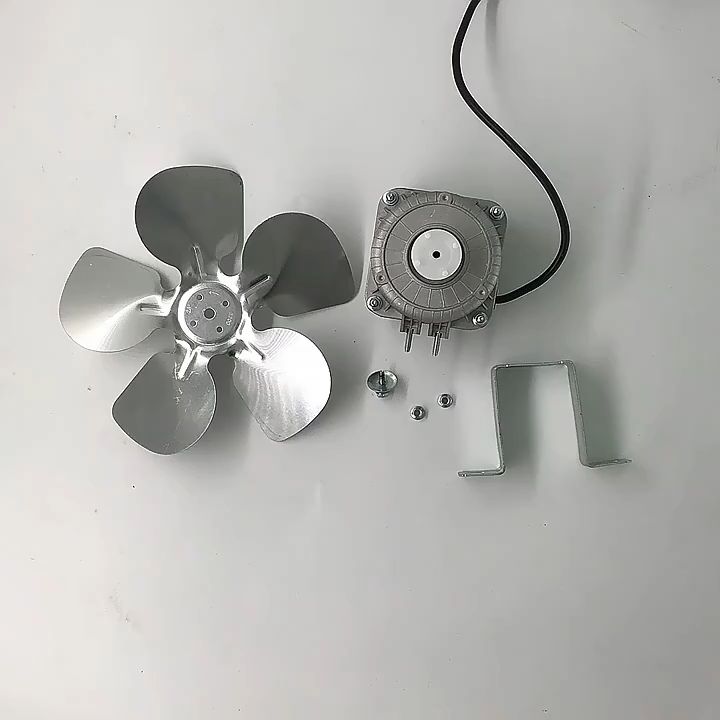

Finstar Industrial Systems offers its advanced range of Condenser fans. These sturdy and dependable Condenser fans work in conjunction with the condenser coils in an air conditioning or refrigeration system. Their primary function is to enhance heat transfer by forcing air over the coils, which helps cool the refrigerant inside.

Types of Condenser Fans

Axial Fans:

- Description: These fans have blades that move air parallel to the shaft around which the blades rotate. They are commonly used in HVAC systems due to their efficiency and ability to move large volumes of air.

- Applications: Used in residential, commercial, and industrial air conditioning and refrigeration systems.

- Advantages: High airflow, relatively low cost, and simple design.

Centrifugal Fans:

- Description: These fans move air perpendicular to the intake of the fan, using a spinning impeller to increase the air pressure. They are often used when higher pressure is needed.

- Applications: Used in larger HVAC systems and industrial applications where high static pressure is required.

- Advantages: Can handle higher static pressures, quieter operation compared to axial fans at lower speeds.

Key Features and Considerations

- Material: Typically made from durable materials such as aluminum, steel, or high-quality plastics to withstand outdoor conditions and continuous operation.

- Size and Capacity: Selected based on the size of the condenser and the cooling capacity required. Proper sizing is crucial for efficient system operation.

- Motor Type: Can be direct drive (motor directly connected to the fan) or belt drive (motor connected to the fan via a belt). Direct drive is simpler and requires less maintenance, while belt drive can handle higher loads and offer adjustable speeds.

- Speed Control: Some condenser fans come with variable speed controls to adjust airflow based on cooling demand, improving energy efficiency.

- Noise Level: Important for residential and commercial applications, especially in noise-sensitive environments.

Applications

- Residential Air Conditioning Systems: Used in central air conditioning units and heat pumps to dissipate heat from the condenser coils.

- Commercial HVAC Systems: Essential in rooftop units, split systems, and large commercial air conditioning systems.

- Industrial Refrigeration: Used in industrial chillers, walk-in coolers, and refrigeration systems to maintain optimal temperatures.

- Automotive Air Conditioning: Automotive condenser fans help cool the refrigerant in vehicle air conditioning systems.

Advantages

- Improved Heat Dissipation: Enhances the efficiency of the refrigeration cycle by effectively dissipating heat from the condenser.

- Energy Efficiency: Properly sized and controlled fans can reduce energy consumption in HVAC systems.

- Extended Equipment Life: Helps prevent overheating of the system, extending the lifespan of the compressor and other components.

Maintenance and Troubleshooting

- Regular Cleaning: Keep the fan blades, motor, and surrounding area clean to prevent dirt and debris buildup that can impede airflow and efficiency.

- Lubrication: Ensure moving parts are properly lubricated, especially in belt-driven fans, to reduce wear and tear.

- Inspect Electrical Connections: Regularly check electrical connections and wiring for signs of wear or damage.

- Monitor Noise Levels: Unusual noises can indicate issues such as loose components, imbalanced blades, or motor problems.

- Check for Vibrations: Excessive vibrations can signal imbalanced blades or motor problems. Address these issues promptly to prevent further damage.

- Replace Worn Components: Periodically replace worn or damaged fan blades, motors, belts, and other components to maintain optimal performance.

Conclusion

Condenser fans play a critical role in the efficient operation of air conditioning and refrigeration systems by facilitating heat transfer from the condenser coils. Selecting the right type of fan, ensuring proper maintenance, and addressing issues promptly are essential for the longevity and efficiency of these systems. Properly functioning condenser fans contribute to energy efficiency, system reliability, and overall cooling performance in residential, commercial, and industrial applications.

Other products

email @