Description

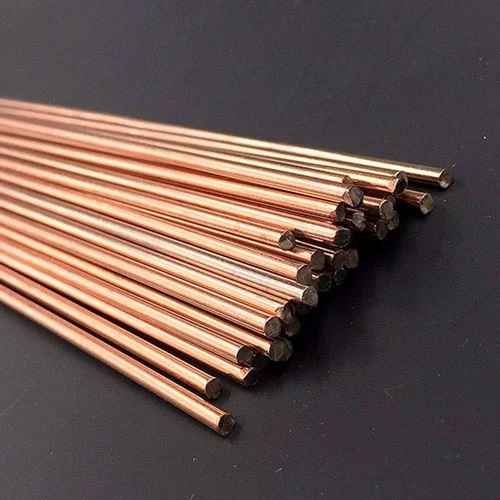

An In-Depth Look at Copper Pipes in Refrigeration

At Finstar Industrial Systems, we fully understand how essential copper pipes are to refrigeration systems. Because of their critical role, we make it a priority to educate our customers about their importance. Furthermore, we provide detailed insights into how these pipes function, ensuring that our clients make informed decisions before purchasing. Consequently, they can trust that Finstar Industrial Systems delivers the best copper pipes for their refrigeration needs. By choosing us, you gain not only quality products but also valuable expertise to support your success in every project.

he Role and Benefits of Copper Pipes in Refrigeration

At Finstar Industrial Systems, we recognize the critical importance of copper pipes in refrigeration. To empower our customers, we clearly present the roles and benefits of before they make a purchase. This ensures they understand how these pipes enhance refrigeration systems, building trust in Finstar as the go-to supplier for top-quality products.

Roles of Copper Pipes in Refrigeration

1. Refrigerant Transport

- Evaporator to Compressor: Carry low-pressure refrigerant vapor efficiently.

- Compressor to Condenser: They transfer high-pressure refrigerant gas with precision.

- Condenser to Expansion Valve: The pipes ensure seamless movement of high-pressure liquid refrigerant.

- Expansion Valve to Evaporator: These pipes facilitate the transfer of low-pressure liquid refrigerant effectively.

2. Heat Exchange

- Evaporators and Condensers: With excellent thermal conductivity, maximize heat transfer, boosting efficiency.

3. Connection and Integration

- Connecting Components: They link compressors, condensers, evaporators, and expansion valves for a sealed and efficient refrigerant pathway.

- System Integration: They help integrate components seamlessly, ensuring smooth operation.

4. Expansion and Flexibility

- Expansion Lines: It manage refrigerant flow and pressure drops effectively during the expansion phase.

- Flexible Routing: Their flexibility allows easy bending around obstacles, minimizing the need for extra fittings.

Benefits of Copper Pipes in Refrigeration

1. Excellent Thermal Conductivity

High thermal conductivity ensures optimal heat transfer, crucial for efficient evaporators and condensers.

2. Corrosion Resistance

Copper resists corrosion naturally, maintaining system integrity and extending lifespan, especially in moist environments.

3. Durability and Strength

Copper’s durability withstands high pressures and temperature variations, making it dependable and long-lasting.

4. Flexibility and Easy Installation

Soft copper tubing simplifies installation by reducing joints and fittings, minimizing potential leaks.

5. Antimicrobial Properties

Copper’s natural antimicrobial properties enhance hygiene by reducing bacterial growth within the pipes.

6. High Pressure Rating

Types K and L pipes handle high pressures, ideal for commercial and industrial refrigeration systems.

7. Leak Tightness

Soldered or brazed joints ensure leak-tight connections, maintaining refrigerant containment.

8. Recyclability

Copper’s 100% recyclability makes it environmentally friendly, conserving resources and reducing waste.

9. Wide Availability

Copper pipes come in various sizes, meeting diverse refrigeration system needs.

10. Compliance with Standards

These pipes meet global safety and quality standards, ensuring reliable and safe operation.

Learn More About Copper Pipes

Discover more about the different types of copper pipes available at Finstar Industrial Systems and why they are the top choice for refrigeration systems.