Description

Finstar Industrial Systems provides a robust range of AC compressors designed to ensure efficient cooling by driving the continuous flow of refrigerant in air conditioning systems. These durable and dependable components are at the core of maintaining comfortable indoor environments.

Key Features

- High-performance operation for effective cooling.

- Durable construction to withstand tough conditions.

- Easy installation and maintenance.

- Energy-efficient solutions for cost savings.

- Customizable to meet diverse cooling requirements.

Functions of AC Compressors

- Compressing Refrigerant: Increases the refrigerant’s pressure and temperature, preparing it for heat exchange.

- Circulating Refrigerant: Pumps the refrigerant through the system, enabling the cooling cycle.

- Heat Exchange: Facilitates heat release through the condenser coil, resulting in cooler indoor spaces.

Types of AC Compressors

- Reciprocating Compressors: Use a piston mechanism to compress refrigerant. They are robust and common in residential and commercial applications.

- Rotary Compressors: Employ a rotating mechanism for compression, making them compact, quiet, and efficient—ideal for small systems like window units.

- Scroll Compressors: Feature two spiral scrolls for compression, offering quiet operation and high efficiency, often used in residential and light commercial systems.

- Screw Compressors: Use helical rotors to handle large refrigerant volumes, ideal for industrial and large commercial systems.

- Centrifugal Compressors: Utilize a rotating impeller for efficient cooling, especially in large-capacity systems.

Maintenance Tips

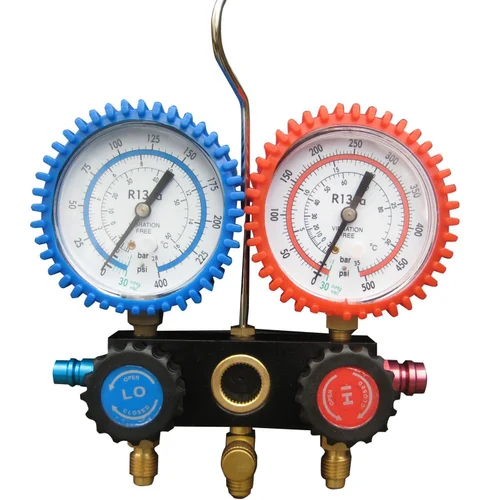

- Regular Inspections: Check for refrigerant leaks, unusual noises, and electrical connections.

- Clean Coils and Filters: Prevent overheating and inefficiencies by keeping components clean.

- Monitor Refrigerant Levels: Ensure proper refrigerant charge for optimal performance.

- Lubrication: Maintain adequate lubrication to minimize wear.

- Professional Servicing: Schedule yearly professional maintenance to address issues proactively.

Understanding the functions, types, and maintenance needs of AC compressors is essential for ensuring efficient performance and prolonging the lifespan of air conditioning systems. Proper care, including regular inspections, cleaning, and professional servicing, helps optimize cooling, reduce energy costs, and prevent breakdowns, ensuring reliable operation in residential and commercial settings.

For more details or to place an order, reach us through:

Email: finstarindustrialsystems@gmail.com

Phone: +254 726 559 606