Description

Key considerations of using Copper pipes in Refrigeration

The following are considerations of using copper pipes in refrigeration

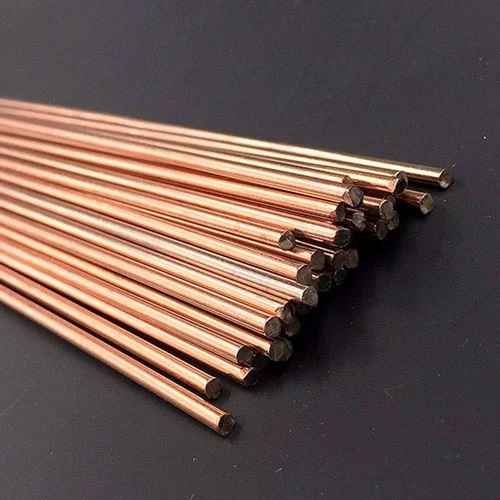

1. Pressure Ratings

- Operating Pressure: Ensure the copper tubing can handle the system’s maximum operating pressure. Types K, L, and ACR copper tubing are commonly used for their high pressure ratings.

- Safety Margin: Select tubing with a pressure rating well above the system’s maximum operating pressure to provide a safety margin.

2. Size and Diameter and Considerations for Using Copper Pipes in Refrigeration

- Tubing Diameter: Match the diameter of the copper tubing to the refrigerant flow requirements of the system. Proper sizing is crucial for maintaining efficient refrigerant flow and avoiding pressure drops.

- Length of Roll: Determine the length of the copper roll needed based on the layout and design of the refrigeration system.

3. Wall Thickness Considerations for Using Copper Pipes in Refrigeration

- Type K: Has the thickest walls, providing the highest pressure rating, suitable for high-pressure refrigerant lines and underground installations.

- Type L: Has medium wall thickness, offering a balance between strength and flexibility, commonly used in residential and commercial refrigeration systems.

- Type M: Has the thinnest walls, generally used for low-pressure applications, less common in refrigeration due to lower pressure ratings.

4. Flexibility and Installation

- Soft Copper Tubing: Offers greater flexibility and can be easily bent and routed around obstacles, reducing the need for fittings and minimizing potential leak points.

- Hard Copper Tubing: More rigid and durable, suitable for straight runs and areas where structural integrity is essential.

5. Corrosion Resistance

- Environmental Conditions: Consider the installation environment. Copper tubing should resist corrosion from exposure to moisture, chemicals, and varying temperatures.

- Protective Measures: Use coated or insulated copper tubing in harsh environments to extend the lifespan of the piping.

6. Thermal Conductivity

- Efficiency: Copper’s excellent thermal conductivity ensures efficient heat transfer, which is essential for effective refrigeration.

7. Cleanliness and Contamination Control

- Pre-Cleaned Tubing: ACR (Air Conditioning and Refrigeration) copper tubing is often cleaned, dehydrated, and sealed to prevent contamination.

- Handling: Keep tubing sealed until installation and handle it with clean gloves to avoid introducing contaminants into the refrigeration system.

8. Insulation Requirements and Considerations for Using Copper Pipes in Refrigeration

- Preventing Heat Gain/Loss: Insulate copper refrigerant lines to prevent unwanted heat gain or loss, which can affect system efficiency.

- Condensation Control: Proper insulation helps prevent condensation on the external surface of the tubing, which can lead to water damage and corrosion.

-

11. Future Maintenance and Accessibility

- Ease of Maintenance: Consider the accessibility of the copper tubing for future maintenance and repairs.

- Documentation: Keep detailed records of the type and specifications of the copper tubing used for future reference.