Description

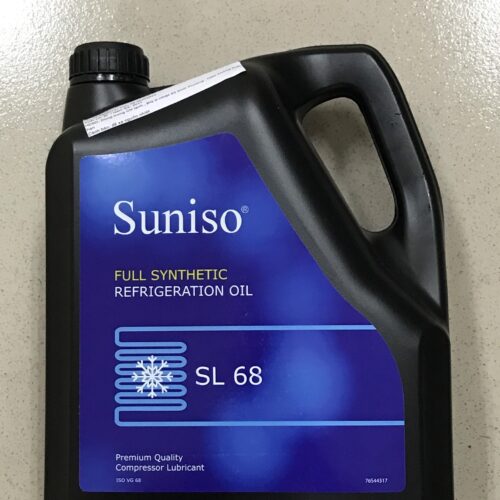

Refrigerant oils, also known as compressor lubricants, are essential components in refrigeration systems that serve to lubricate the compressor’s moving parts, reduce friction, and prevent wear. These oils circulate throughout the system, providing lubrication and helping to remove contaminants and moisture. The type of refrigerant oil used in a system must be carefully selected based on its compatibility with the specific refrigerant, as well as its ability to maintain proper viscosity and lubrication properties under varying temperature and pressure conditions.

Key Features of refrigerant oils

- Appropriate viscosity grade and viscosity index for the operating temperature range

- Good lubrication properties, wear protection, and miscibility with the refrigerant

- Chemical stability and resistance to thermal breakdown

- Low moisture absorption and desiccant properties

- Good heat transfer properties for efficient system operation

- Availability in various viscosity grades and formulations for different applications

- Compliance with environmental regulations and safety standards

- Packaging and handling guidelines for proper storage and use

- Recommended oil charge and replenishment procedures for system maintenance

Functions

- Lubrication: Reduces friction and wear between the moving parts of the compressor, such as pistons, bearings, and shafts.

- Cooling: Helps dissipate heat generated by the compressor during operation, preventing overheating and ensuring efficient performance.

- Sealing: Aids in sealing gaps and maintaining pressure within the compressor, which improves its efficiency.

- Protection: Prevents corrosion and rust on the internal surfaces of the compressor by providing a protective layer.

Factors to Consider When Choosing Refrigerant Oils

- Compatibility with Refrigerant: Ensure the oil is compatible with the type of refrigerant used in the system.

- Viscosity: Select the appropriate viscosity grade based on the compressor manufacturer’s recommendations and the operating conditions of the system.

- Lubricity: The oil should provide adequate lubrication to minimize wear and extend the lifespan of the compressor.

- Stability: The oil should be chemically stable and not break down under the system’s operating conditions, including temperature and pressure variations.

- Moisture Tolerance: The oil should have low hygroscopicity (ability to absorb moisture) to prevent moisture-related issues like acid formation and corrosion.

Selecting the correct refrigerant oil and maintaining proper oil levels and quality are crucial for ensuring compressor reliability, system efficiency, and longevity in refrigeration applications.

For more information or to place an order, reach out to us at:

Email: finstarindustrialsystems@gmail.com

Phone: +254 726 559 606

Choose Finstar Industrial Systems for high-quality refrigerant oils that ensure efficient performance and extend the lifespan of your refrigeration systems. Our oils are designed for optimal lubrication, enhancing the reliability and operation of compressors and cooling units. Trust Finstar for premium refrigerant oils that meet your needs and exceed expectations.